Cloth Material Cutting Rubber Asbestos Cork PTFE Gasket CNC Vibratory Knife Cutting Machine

Production: Cloth Material Cutting Rubber Asbestos Cork PTFE Gasket CNC vibratory knife cutting machine Application of v

Basic Info

| Model NO. | KJZD1625 |

| Waterproof Rating | IPX-0 |

| Warranty | 1-year |

| Certification | CE, ISO 9001:2000, ISO 9001:2008 |

| Condition | New |

| Control | Automatic |

| Application | Paper, Plastic, Leather, Fabric |

| Power Source | Electric |

| Layout | Horizontal |

| Voltage | 110/220/380V |

| Power | 9-11kw |

| Cutting Speed | 1500mm/S |

| Cutting Thickness | 50mm |

| Safety Device | Infrared Radiation/Anti-Collision/Emergency Stop |

| Transport Package | Wooden Box |

| Specification | 1600*2500mm |

| Trademark | kangjia |

| Origin | Jinan China |

| HS Code | 8461500090 |

| Production Capacity | 100 Unit / Month |

Product Description

Production: Cloth Material Cutting Rubber Asbestos Cork PTFE Gasket CNC vibratory knife cutting machine

| Model | 1625/1630/1830/2030 optional |

| Working area | 1600*2500mm / 1600*3000mm / 1800*3000mm / 2000*3000mm |

| Rated power | 7-11KW |

| Fixed mode | Flat table /auto feeding table optional , table structure: whole welding process |

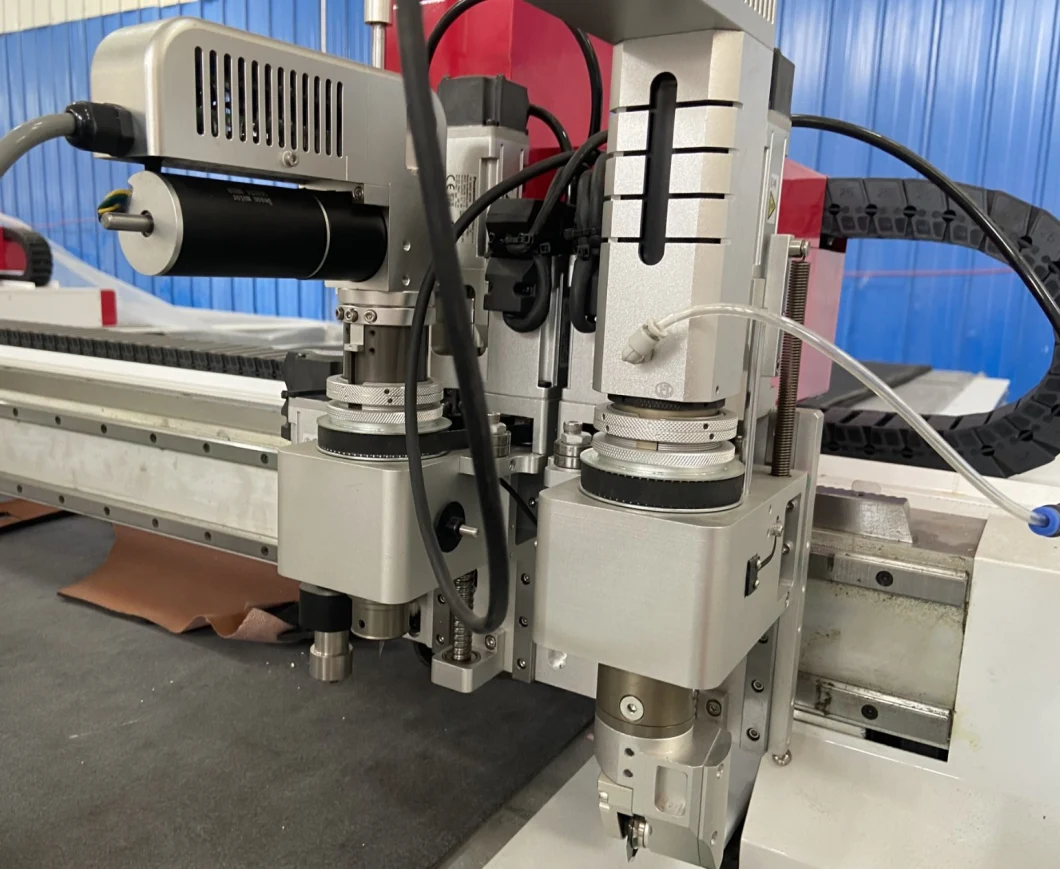

| Multifunctional heads optional | Vibration knife (oscillatory knife) |

| Circular knife (round knife / rotary knife) | |

| Oblique knife (V-cut) | |

| Marking pen | |

| Punching roller (round punching/v-punching/optional) | |

| Milling knife | |

| Drag knife | |

| Pneumatic knife | |

| Projector and camera optional | |

| Safety device | Using infrared sensors, mechanical safty device, Intelligent anti-collision device responsive, safe and reliable. |

| Material feeding type | Auto feeding or manual feeding |

| Material fixed type | Vac-sorb (vacuum absorption), suction fan power: 2.2kw / 7.5kw / 9kw |

| Translational velocity | 800-1500mm/s |

| Cutting speed | Max. 1500mm/s (according to different cutting materials) |

| Cutting thickess | ≤60mm (according to different cutting materials) |

| Cutting material | Fabric, all kinds of clothing flexible material, Sponge leather, PVC, soft glass, Silicon, rubber, cardboard etc. |

| Repated accuracy | ≤0.1mm |

| Cutting type | Mechanical vibration physical cutting |

| Transmission / driving system | Motor brand Panasonic, YASKAWA, Fuji, Delta |

| Transmission type / Guide rail | Digital servo motor, linear guide, synchronous belt, rack/spline, ball screw |

| Instruction system | HP-GL compatible format |

| Control system | LCD touch screem ( custom made) |

| Voltage | 220V / 380V±10%; 50HZ, 60HZ |

| Other configuration | Germany imported conveyor belt, vacuum table, Taiwan Hiwin rail, vacuum pump |

Application of vibrating knife cutting machine

Osciliting knife cutting machine can cut fabric, leather, cardboard, plastic, paper, rubber, EVA foam, and it can cut many types of foam, such as closed cell foam, rubber foam, foamex, foam core, KT board, EPE foam, polyethylene foam, PE foam, PVC foam, etc. It's widely used for packaging protection, advertising display, termal insulation, model & mock up making, puzzle and pattern cutting, etc.

What materials can I cut with an oscillating knife?

The oscillating knife option can cut a range of materials, here is a few that spring to mind:- Medium density foam

- Rubber

- Card

- Fabrics/textiles

- Correx

- Fibreboard

About usJinan Kangjia CNC Equipment has focused on CNC equipment production for over 5 years. It is a comprehensive service factory specializing in the production, sales and technical service of oscillating knife cutting machine. It covers multiple fields and industries, such as automotive decoration, toys, garment, leather product, furniture etc. Its R&D level and production capacity has always been in the leading position in the same industry. Our factory is located in Jinan city of China. It covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month.

CertificationExhibitionPacking and delivery

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

After-Sales Service

1.12 months quality guaranty (laser tube is 6 months), the machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

2. Free training course at our plant.

3. We will provide the consumable parts at an agency price when you need replacement.

4. 24 hours on line service each day, free technical support.

5. Our staff can be sent to your company to install or adjust if necessary.

Advantages of oscillating knife cutter cutting:

1. Knife cutting technology, non-laser cutting, no scorching, discoloration, no odor, and flat cut.

2. CNC cutting replaces the traditional manual development design and proofing, shortening the corresponding development time.

3. Quickly shaped cutting without the need of a die to meet the customer's production goals of small batches and multiple styles, creating a standardized and practical complete solution.

Features of Oscillating Knife Cutting Machine:

1. It can automatically discharge and cut the entire sheet; (reducing the fixing device that needs to be replaced before to complete the tedious unloading process)

2. With vacuum suction function, avoid cutting product movement and improve output;

3. Easy installation, easy operation, saving labor intensity and improving efficiency.

Send to us